Laboratory of local ventilation systems

The Department of Thermodynamics and Environmental Engineering runs a laboratory of ventilation systems that is

fitted with high quality experimental equipment and advanced instrumentation.The laboratory allows to solve a wide

spectrum of problems associated with air flow with the use of advanced optical methods. It is intended and accordingly

equipped for testing of devices that are associated with ventilation of rooms or vehicle cabins. The current research

carried out at the laboratory focuses on car vents development and their measurement in operation; the fundamental

research conducted concerns pipe flow and close-to-wall flow.

The Department of Thermodynamics and Environmental Engineering runs a laboratory of ventilation systems that is

fitted with high quality experimental equipment and advanced instrumentation.The laboratory allows to solve a wide

spectrum of problems associated with air flow with the use of advanced optical methods. It is intended and accordingly

equipped for testing of devices that are associated with ventilation of rooms or vehicle cabins. The current research

carried out at the laboratory focuses on car vents development and their measurement in operation; the fundamental

research conducted concerns pipe flow and close-to-wall flow.

Laboratory equipment

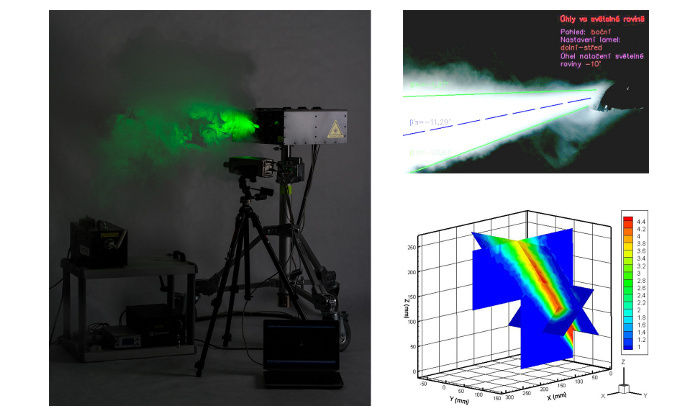

There are number of advanced diagnostic methods available to study fluid flow at the laboratory such as laser Doppler anemometry or Particle Image Velocimetry, but also traditional yet still developing methods such as hot-wire anemometry. For flow visualization, the method of smoke, fog or bubbles introduction is employed in combination with laser sheet and high-speed camera recording.

The computer controlled measurement is conducted under LabVIEW interface by National Instruments and covers common flow parameters such as flow rate, pressure drop and temperature but also parameters related to environmental engineering such as noise and vibrations, pressure in the fluid, temperature. For results visualization and processing the following codes are used: Origin, Tecplot, AutoCAD and Matlab.

Laboratory instruments

- StreamLine Hot-wire anemometer by Dantec Dynamics

- Solid-state laser light sheet

- Particle Image Velocimetry (PIV) by TSI Inc.

- Helium bubble generator SAI Model 5

- Olympus i-Speed 2 high speed camera

- System for noise and vibration diagnostics

References

- Škoda auto a.s. (Analysis of directionality and homogeneity of an air jet issuing from dashboard vents. Flow around defrost vent of a dashboard) (2007-2011)

- Evektor, spol. s r.o. (Flow visualization. Visualization of Coanda effect) (2007-2009)

- Honeywell, spol. s r.o.: Air-conditioning unit design for turbocharger testing (2011)

- TTS eko s.r.o. Třebíč (Assessment of possible noise reduction in an ORC co-generation unit control room. Characteristics of noise generated by an ORC co-generation unit) (2005)

- Busch Vakuum s.r.o. (Analysis of the pressure in the vacuum pump suction manifold during production cycle at Technistone production plant) (2007-2008)

- SOMA Lanškroun, Development of a drying system for flexographic printing lines MINI and QUICK (2004, 2005), New generation of flexographic printing machines (2006), Development of extraction system for longitudinal cutting machines BMS/Compact (2005)

Related publications

- Lezovic T., Lizal F., Jedelsky J., Jicha M., HVAC automotive vents evaluation and their performance, HVAC&R Research 19 (2013) 8, 1073-1082 (ISSN 1078-9669)

Other outputs

Contact person

Jan Jedelsky, Ph.D., Associate Professor

phone: +420 54114 3266 | e-mail: jedelsky@fme vutbr

vutbr cz

cz

Energy Institute, Department of Thermodynamics and Environmental Engineering

Faculty of Mechanical Engineering, Brno University of Technology

Technicka 2896/2, 616 69 Brno, Czech Republic

Download the above information as a brochure in  PDF (520 KB) nebo

PDF (520 KB) nebo  JPG (430 KB).

JPG (430 KB).